For the last 25 years, lighting manufacturers have been in a fierce competition to out-shine each other. The focus of modern manufacturers’ has been one-upping the next with more lumens from their latest fixture. Specifically with regard to emergency vehicle LED lighting technologies, we saw fixtures in the 10,000 lumen range initially, then 15,000 lumens, 5 or so years ago we saw manufacturers begin advertising light output 20,000 lumens + and more recently, manufacturers are touting 28-30,000 lumens.

When is enough, enough? Does MORE lumens at the source of LED emergency lights equate to safer firefighters on the fire scene?

I just attended a Fire Apparatus Manufacturers Association event in Arizona (USA) where truck builders and suppliers get together to discuss trends in the emergency vehicle lighting industry. One of the presenters, while discussing trade show effectiveness, asked us “imagine you’re a manufacturer of tools; drill bits specifically. When you’re at the show, how do you explain your product to your customer?” His discussion of the topic explained that instead of focusing on making strong or high quality drill bits, the message was really that you enable people to drill really good holes. Nobody buys a drill bit because they love drilling, they buy a drill bit because they need a hole in something.

Using that logic, when we speak about lighting, we should be asking the question “What am I trying to accomplish?” And “Do I need a really bright light, or do I need to be able to see to do my job after dark?”

My bet is the latter is more important than the former. Assuming that statement to be accurate, lets explore some of the practical applications that can help accomplish that job.

Keeping Fire Firefighters Safe with LED Scene Lighting

When we speak about lighting, we should be asking the question “What am I trying to accomplish?” And “Do I need a really bright light, or do I need to be able to see to do my job after dark?”

My bet is the latter is more important than the former. Assuming that statement to be accurate, lets explore some of the practical applications that can help accomplish the job.

-

LED scene lighting: High quantity with less overall intensity.

Often, I am asked “what’s the most important factor to consider when lighting a fire scene?” The answer is not how bright it is, but how consistent the light level is. Think about walking inside a dim office from a bright outdoor location on a summer day: It takes your eyes a few seconds to adjust to the difference in light level. Once adjusted, the lower intensity inside the building ends up being acceptable to work under. The same principle applies at night. If a firefighter near the apparatus goes from an extremely bright area on one side of the rig, through a darker spot, then back to a bright area, their eyes have to work to adjust and compensate for the changing light levels.

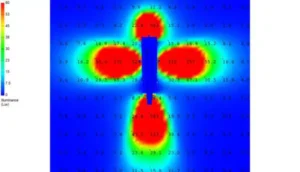

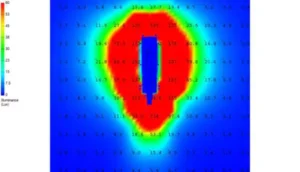

By using smaller fixtures placed more often around the body of the apparatus, versus just a few extremely high output fixtures, the highs and lows can be reduced. Having a more even light pattern around the apparatus can be one of the most effective changes made in your fleet to improve nighttime visibility. The cost of 4 small fixtures often ends up roughly the same as a fixture with a total cumulative lumen total similar to the set.

Pictured here are two examples of trucks. The first is a truck with 4x 20,000 lumen scene lights installed midship on the body, one on the rear, and one on the brow edge. The second truck is an example showing 10 smaller fixtures, 8,000 lumens each, spread out around the apparatus. These two set ups produce similar total volume of light, put the placement of the light on the second truck is clearly advantageous.

These two configurations cost the same and create the same number of “Lumens”. The bottom image shows optimized placement.

-

With LED scene lights, the COLOR of the light makes a difference.

One measurement not often mentioned in the fire service is the “Color Temperature” of the light produced by the fixture. Color temperature, in its most simple form, is the measure of how amber/yellow/orange, or how white/blue/purple the light is. Color Temp is measured in Degrees Kelvin. 2800k is typically in the amber color spectrum, while 5,000 is much more “white” and 7000k is blueish or purple.

In modern firefighting, choosing a fixture in the 5-6,000k range is usually a safe choice. However, in some specialty applications this choice can be more impactful. Rescue or hazardous materials response apparatus can benefit from a high color temperature. The higher color temperature ~6,000k has a shorter wavelength and reflects off particulate (smoke, steam etc) much better. In HAZMAT, its important to be able to tell if the railcar you’re working on suddenly vents a cloud of chlorine, or if the pile of spilled oxidizer substance is off gassing and reacting with the environment it is in. High color temperature lighting can help responders see little changes faster. Or make those changes more noticeable.

Inversely, imagine an application like fighting a wildland fire where dense organic smoke is often in and around the work area. In environments with heavy saturation of particulate in the environment (dusty, smoky environments), using a color temperature with a slightly longer wavelength, 2800-4500k has advantages due to being less prone to reflect back and blind the operator.

Think about it this way: when the sun rises and sets, the color of the light is typically orange. At high noon, the light color is more white. One of the principle reasons behind the change in perceived color of the sun is the particulate debris in the lower atmosphere filters out light in the shorter wavelengths, only allowing the amber and orange light to reach your eye when the length is greatest from you to the sun. The whites and high color temperature light are reflected back towards the source. If you are standing at the source, and only emit light in a spectrum that is not likely to bounce off the particulate into eh atmosphere, the likelihood of bounce back and glare can be reduced.

- High color temperature in rescue environments where dexterity is important

- Low color temperature in environments where dense organic smoke, filled with particulate debris, can be used to reduce bounceback

-

Better thermal management yields sustained light output

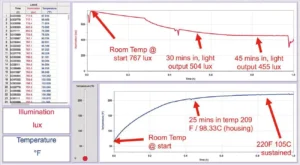

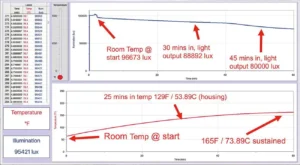

Both fixtures advertised as “20,000lm”. The bottom fixture is very thin and degrades more than 40% over 1 hour due to thermal runaway. The top fixture is thick and more efficient, only degrades 17.25% in the same time frame.

One factor often overlooked by fire apparatus manufacturers and specifying comities is the ability of the fixture to manage its thermal load. People gravitate towards thin fixtures because they are easier to carry, easier to manipulate and raise on poles/tripods. However, when a cross section of fixtures from the industry is measured, the fixtures with more thermal mass, and better ability to dissipate heat typically outperform in the long run. Some very popular fixtures get so hot, the measured light output after 30 minutes can be measured with up to 45% degradation.

If you were to take a 150 watt circuit board out of any manufacturers fixture, and attach it to the housing of every manufacturer’s fixture, you would notice a significant difference in performance based only on the design of the housing.

How can you ensure you get maximum bang for your buck? Request thermal degradation data from the light manufacturer before you specify it or set the test up in your fire station.

Take a light fixture, plug it in to a known power source, put a light meter on the ground at a pre-set distance from the fixture, and write down the measurements every 5 minutes for an hour. After 1 hour, if the number has stopped dropping, you can consider the fixture “thermally saturated” and calculate the percentage of reduction in output. The number on the meter is less important, but the percentage difference from the highest to the lowest is what’s important.

All fixtures will have some degree of degradation; 15-20% is normal. Anything higher than that indicates a problem with thermal management, which will ultimately reduce the lifespan of the circuit and cause unpredictable light levels on your fire scene.

-

Get your LED scene lights up in the air!

When designing a lighting package, one of the common questions asked is “where should I mount the fixtures?” The short answer is, most of the time, as high as possible. Think about the natural shape of the human face: two eyes, symmetrically placed on either side of the scull, recessed back in towards the center of the upper cranium. Humans have eyelids, eye lashes, and eyebrows. If we use this shape to our advantage, those structures on the face can act like the bill of a hat to prevent glare from hitting us directly in the eyes. Elevating the light in the air shining down on the fire scene not only reduces unnatural shadows, but also takes advantage of the natural shape of the human head to keep light out of the eyes of the first responder.

In conclusion, scene lighting can be a complicated topic. If you break it down and change your perspective, solve the problem “how do I help my firefighters see at night” not “how many lumens can I pack in to this space on my apparatus” and you are sure to see an improvement in the your crew’s nighttime effectiveness.

About HiViz LED Lighting

Sam Massa is the president and Chief Technologist for HiViz LED Lighting and the FireTech brand. Sam is an American Firefighter/EMT and Hazardous Materials Technician based in North Carolina, as well as a technical specialist in areas of scene lights. Sam is a member of the North American “Fire Apparatus Manufacturers’ Association” and has provided input and public comment on language adopted in to the NFPA 1901 Standard for Automotive Fire Apparatus. HiViz LED Lighting can be found online at www.hivizleds.com and Sam reached at sam.massa@hivizleds.com